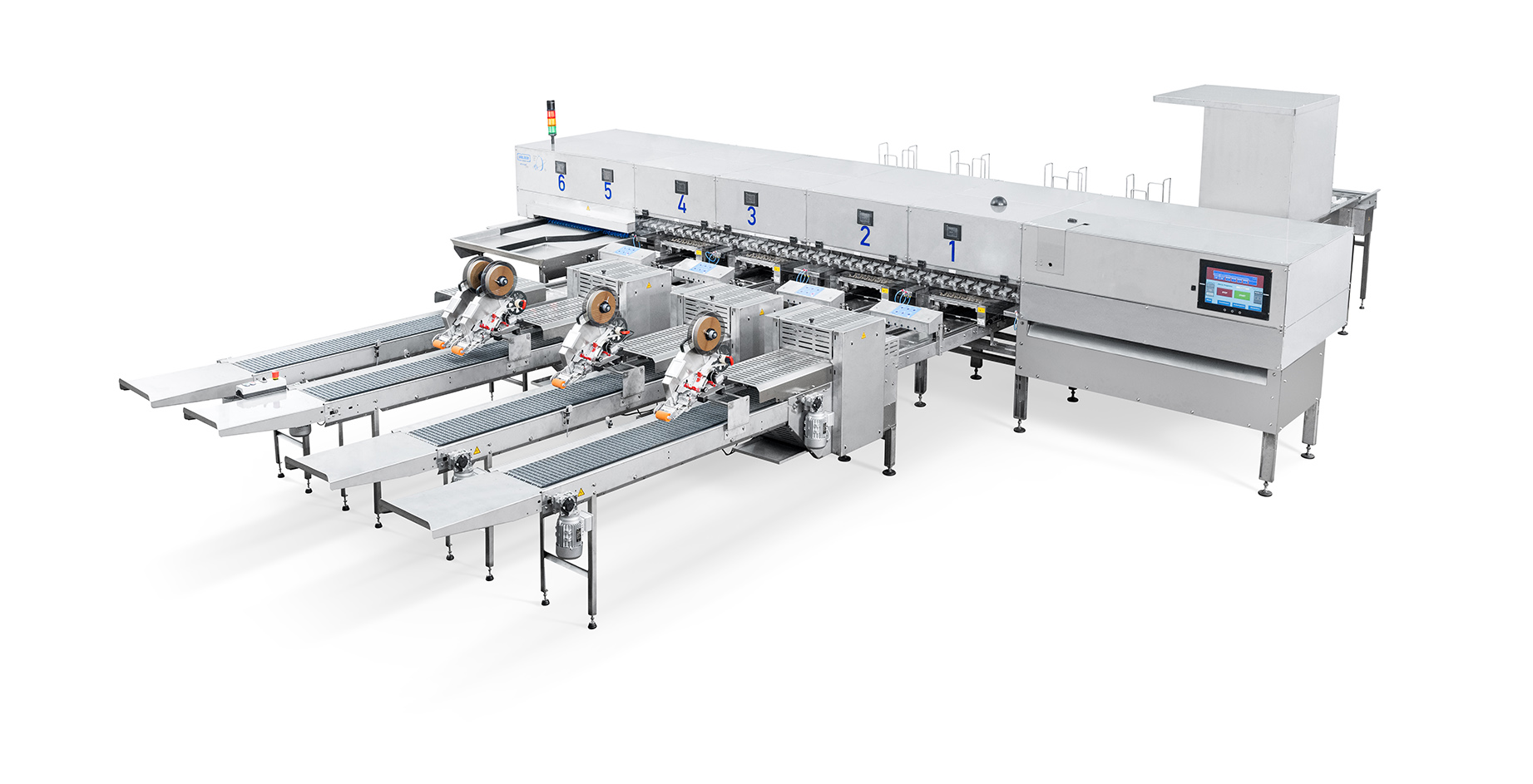

Egg grader with automatic packing lanes:

Egg grader with automatic packing lanes:

Our egg graders in the VSX/VDX 9000, 12000 and 15000 series can be optionally equipped with automatic packing lanes. A packing lane comprises a de-nester, an egg packer, packaging belt and a conveyor belt, and is made of stainless steel. A closer can also be incorporated as an optional extra for sealing small packages.

Our egg graders in the VSX/VDX 9000, 12000 and 15000 series can be optionally equipped with automatic packing lanes. A packing lane comprises a de-nester, an egg packer, packaging belt and a conveyor belt, and is made of stainless steel. A closer can also be incorporated as an optional extra for sealing small packages.

The VÖLKER Novum is a series from our electronically weighing egg grading machine range. Developed and manufactured in Germany using our experience in the field of egg grading machines and Farmpackers gained over very nearly 40 years.

With the Novum, we satisfy the wishes of many grading companies for an egg grading and packing machine with quick and efficient processing of their egg batches.

The VÖLKER Novum series works with a capacity of 20,000 eggs/hour (Novum 55) up to a maximum of 25,000 eggs/hour (Novum 75) using the well-known carousel system with individual egg handling. Thanks to their modular and compact design, they can be adapted to suit virtually all packing rooms.

Egg Infeed:

The infeed of the eggs can take place via the direct connection of the dispensing unit on the egg belt, a placement unit or a combination. The soft-roller table is equipped with an integrated lighting unit with special energy-saving lamps.

Egg Grading and Transport (Single Egg Handling):

Through electronic weighing, the eggs are very accurately graded. The classification of all eggs into one of a maximum of seven different weight classes can be selected on the display. Due to the gentle transport of the eggs from the soft-roller table in front of the weighing units up to them being placed in the packaging and / or on the hand packing table, contact with each other is not possible. Thereby, damage due to contact between the eggs during grading is prevented.

Dropbox:

The VÖLKER Dropbox ensures the accurate and gentle setting down of the eggs in the packaging. Regardless of the type of packaging, the dropbox takes the eggs from the transport carriers and gently puts them down in the packaging. For the assurance of the highest level of hygiene, the dropbox can be completely removed from the packing lane so that its easy, problem-free cleaning is possible.

Brown / White Separation:

The automatic separation of brown and white eggs on the Novum egg grading machine is possible as an option. Here, already at the roller table, the shell colours of the eggs are identified and categorized. Via a straightforwardly designed touch terminal, the operator can then allocate the colours to individual stations so that the eggs can be packed according to type or mixed.

The VÖLKER E-Grader series is the electronic weighing and egg grading machine series for small and medium-sized companies. The E-Grader series is available with capacities of 10,000 eggs/hour and 16,000 eggs per hour and distinguishes itself through its compact design and high degree of user-friendliness. This machine offers producers with limited available space especially the optimum opportunity to increase their efficiency through the fast grading and packing of their eggs and in doing so guarantee their customers a higher level of quality.

Egg Infeed:

As with all our machines, the egg grading machine can be connected directly to the egg conveyor coming out of the hen house. The further developed two-stage dispensing unit ensures the optimum filling of the roller table. After the integrated lighting unit, the highly accurate electronic weighing as well as the automatic allocation of the eggs to the appropriate weight class selected on the display takes place.

As options, direct filling by means of a placing device or a combination of placing device and direct hen house connection (inline/offline-function) are also possible.

Packing Unit:

With the linking of packing lanes, the packing of the eggs takes place using a special packing unit. Through the turning of the eggs inside the packing unit, the setting down of the eggs with the tip pointing downwards is guaranteed to 99.8%. Thanks to the finger transport, setting down is exceptionally gentle for the eggs and contact between the eggs is prevented. The well-thought-out design of the packing unit ensures ease of cleaning and the best accessibility.

Designs:

Due to the entirely in-house manufacture of the machines, during their production we can adapt to the respective space requirements and produce the machines accordingly. As already with all mechanically weighing egg grading machines, we can, in addition, adapt the egg infeed to the on-site conditions in order to optimize the use of the space within the packing centre. No mass production.

Egg Labelling:

Thanks to our many years of experience in the field of egg labelling technology, too, the E-Grader series offer as an option the possibility of printing each individual egg with its own text. Hence, users can quickly and accurately process different batches. The printing can take place, for example, with VÖLKER egg labelling with ink cartridges. Through the continuous further development of inks and ink cartridges, this printing is impressive thanks to the ease of operation, a high degree of availability and the lowest of total operating costs. Warm-up periods or individual flushing and cleaning operations as well as regular maintenance are not necessary.

Packing Lanes:

Our packing lanes have been tried and tested in our egg grading machines for many years and are, therefore, also used in the E-Grader ranges. Through their simple adaptation to the different egg packages, the packing lanes offer a high degree of availability. The VÖLKER packing lanes are always equipped with a packaging de-nester that not only separates and reliably transports small packages on the packing conveyor but also 30 x egg trays.

Our packing lanes can be optionally fitted with an automatic universal closer for small packages. These can automatically completely close virtually all currently available small packages so that the finished package can be taken from the conveyor belt without an additional process step.

Labelling:

The VÖLKER labelling machines from the VLS-series can be linked with the packing lanes without problems. In addition to the saving of expensive working time thanks to a high level of automation, the customer achieves a focussed presentation of all the important information such as, for example, the EAN Code, use by date, weight class as well as other information at a defined position on the packaging. Via a touch screen on the labelling machine, these data can be quickly and easily changed without the need for the use of a separate computer or software. Different label templates can be stored in the machine and can be easily called up. Thanks to the proven thermal printing process, sharp, cost- effective printing of the labels is achieved.

Box Printers:

The VÖLKER box printers can print all the information a label otherwise carries directly on to the egg box. It must be ensured, however, that the surface of the box is made from absorbent material.

Hygiene and Cleaning:

In order to comply with the strictest of hygiene regulations, easy to clean and/or self-cleaning components such as stainless steel and special plastics are exclusively used. Through the use of these materials, it is ensured that many components can be washed with water without it adversely affecting their function.

The VSX/VDX 6000 egg grader is made of robust stainless steel and manufactured using sophisticated technologies. A simple machine was developed through detailed and precise planning. This machine is equipped with an egg conveyor belt to ensure careful transportation of the eggs from the scales to the inspection table as well as compliance with hygiene standards. A lighting unit is also included.

Two types are available thanks to the modular construction. Please contact us for further details!

The VSX/VDX 6000 requires very little maintenance and is characterised by its great ease of use.

Sorting performance:

6,000 eggs / hour

Scales:

The scales – the centrepiece of every sorting machine – are also made of stainless steel. Through regulation of the weights system, every weight class can be set with the highest precision.

Hygiene:

To facilitate cleaning and to ensure a high standard of hygiene, the casing, scales, and egg inspection table in our machines are made from stainless steel as standard.

Options:

An egg counter, egg labelling and a vacuum hand suction nozzle are optionally available for the VSX/VDX 6000.

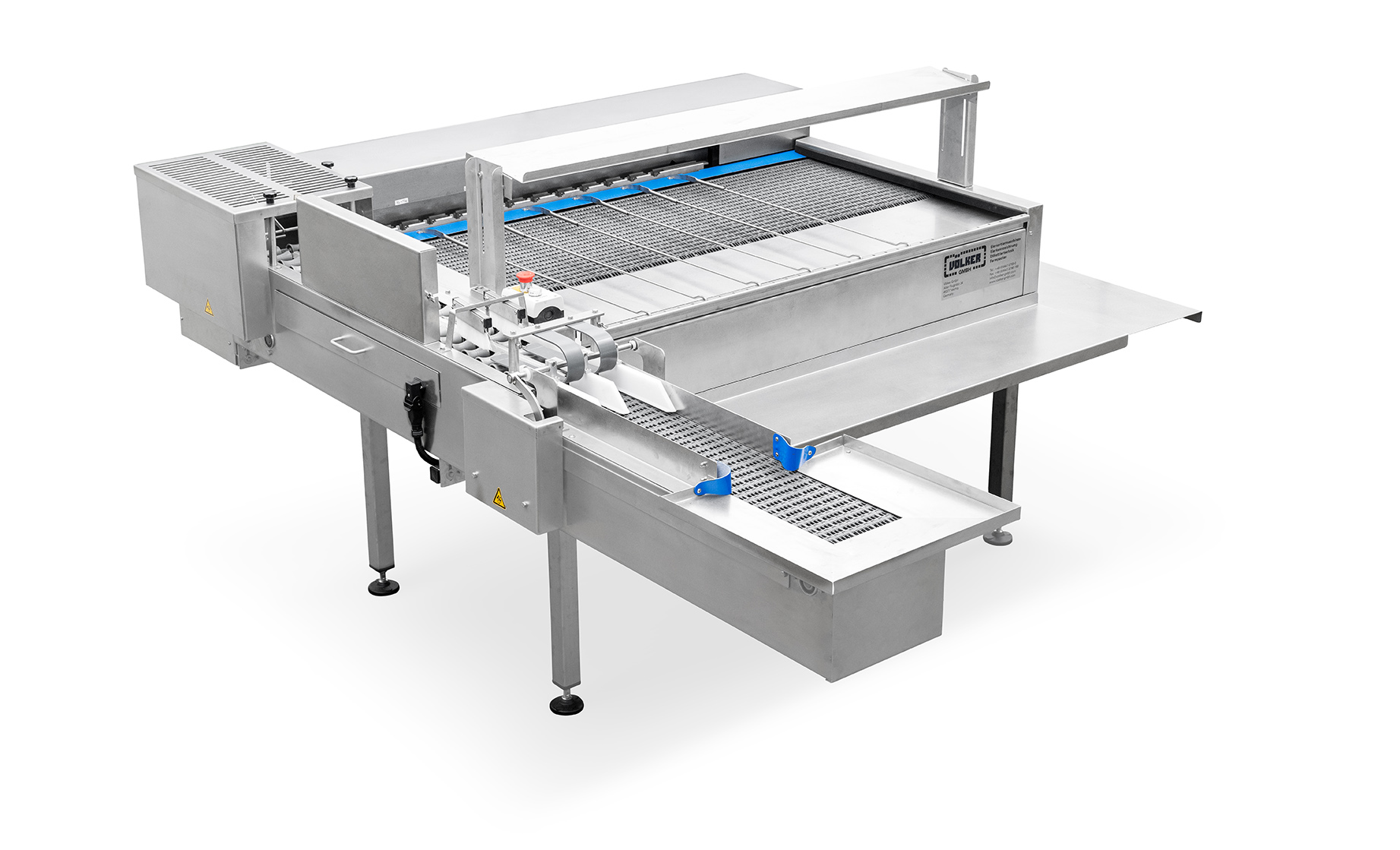

The VSX/VDX 12000/15000 egg graders are made of robust stainless steel and manufactured using sophisticated technologies. A simple machine was developed through detailed and precise planning. This machine is equipped with an egg conveyor belt to ensure careful transportation of the eggs from the scales to the inspection table as well as compliance with hygiene standards. A lighting unit is also included.

Two types are available thanks to the modular construction. Please contact us for further details!

The VSX/VDX 12000/15000 require very little maintenance and are characterised by their great ease of use.

Both machine series are identical by design but differ in terms of their performance in egg sorting.

Sorting performance:

– VSX/VDX 12000: 12,000 eggs/hour

– VSX/VDX 15000: 15,000 eggs/hour

Scales:

The scales – the centrepiece of every sorting machine – are also made of stainless steel. Through regulation of the weights system, every weight class can be set with the highest precision.

Hygiene:

To facilitate cleaning and to ensure a high standard of hygiene, the casing, scales, and egg inspection table in our machines are made from stainless steel as standard.

Options:

An egg counter, egg labelling and a vacuum hand suction nozzle are optionally available for both machines.

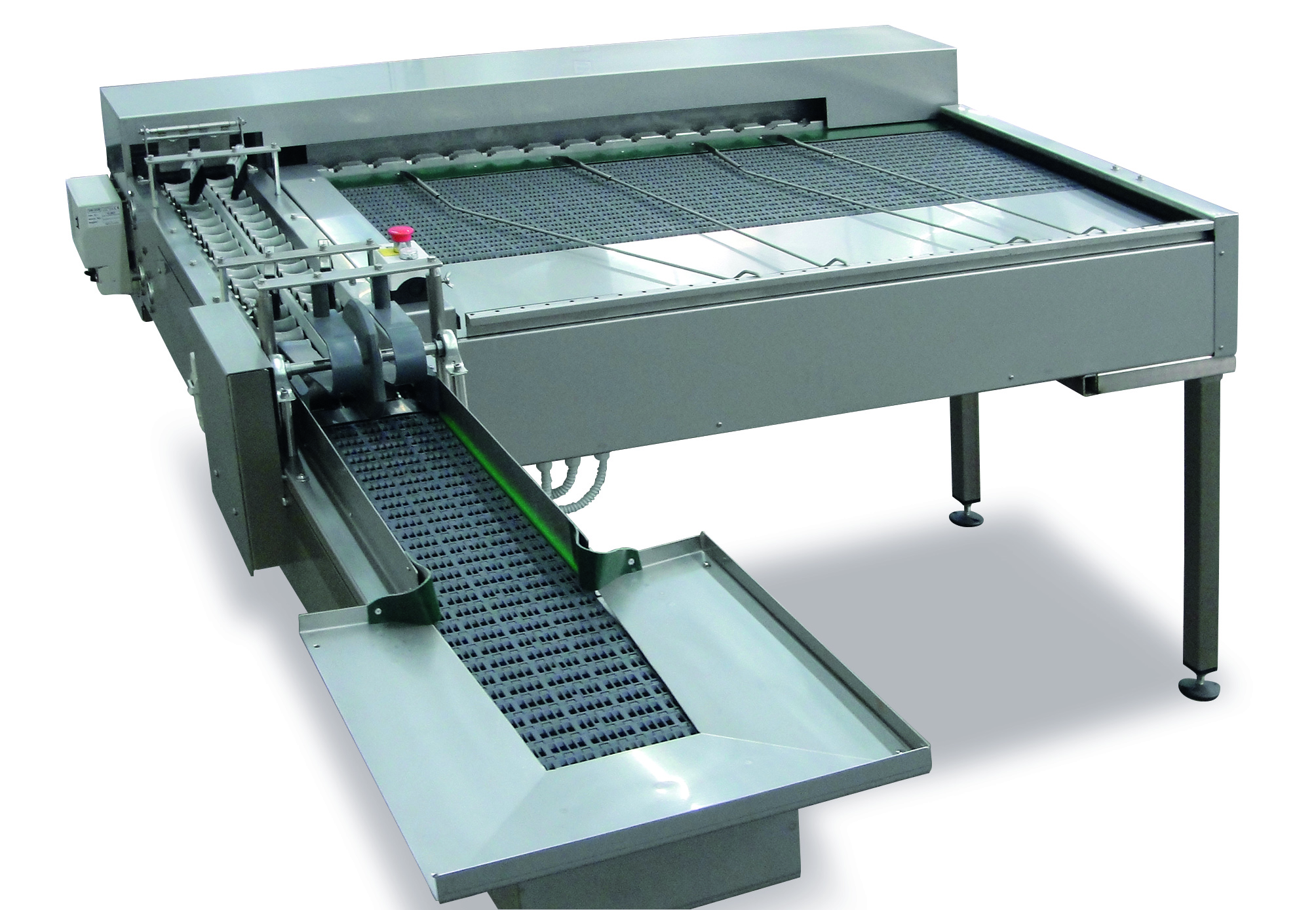

The VSX/VDX 9000 egg grader is made of robust stainless steel and manufactured using sophisticated technologies. A simple machine was developed through detailed and precise planning. This machine is equipped with an egg conveyor belt to ensure careful transportation of the eggs from the scales to the inspection table as well as compliance with hygiene standards. A lighting unit is also included.

Two types are available thanks to the modular construction. Please contact us for further details!

The VSX/VDX 9000 requires very little maintenance and is characterised by its great ease of use.

Sorting performance:

9,000 eggs / hour

Scales:

The scales – the centrepiece of every sorting machine – are also made of stainless steel. Through regulation of the weights system, every weight class can be set with the highest precision.

Hygiene:

To facilitate cleaning and to ensure a high standard of hygiene, the casing, scales, and egg inspection table in our machines are made from stainless steel as standard.

Options:

An egg counter, egg labelling and a vacuum hand suction nozzle are optionally available for the VSX/VDX 9000.

The VSX 4000 egg grader is made of robust stainless steel and manufactured using sophisticated technologies. A simple machine was developed through detailed and precise planning. The VSX 4000 is fitted with a lighting unit as standard.

The VSX 4000 requires very little maintenance and is characterised by its great ease of use.

Sorting performance:

4,680 eggs/hour

Scales:

The scales – the centrepiece of every sorting machine – are also made of stainless steel. Through regulation of the weights system, every weight class can be set with the highest precision.

Hygiene:

To facilitate cleaning and to ensure a high standard of hygiene, the casing, scales, and egg inspection table in our machines are made from stainless steel as standard.

Options:

An egg counter and egg labelling are optionally available for the VSX 4000.

The VSX 3000 egg grader is made of robust stainless steel

and manufactured using sophisticated technologies. A simple machine was

developed through detailed and precise planning. The VSX 3000 is fitted

with a lighting unit as standard.

The VSX 3000 requires very little maintenance and is characterised by its great ease of use.

Sorting performance:

3,000 eggs/hour

Scales:

The scales – the centrepiece of every sorting

machine – are also made of stainless steel. Through regulation of the

weights system, every weight class can be set with the highest

precision.

Hygiene:

To facilitate cleaning and to ensure a high

standard of hygiene, the casing, scales, and egg inspection table in our

machines are made from stainless steel as standard.

Options:

An egg counter and egg labelling are optionally available for the VSX 3000.

The VSX 2000 egg grader is made of robust stainless steel and manufactured using sophisticated technologies. A simple machine was developed through detailed and precise planning. The VSX 2000 is fitted with a lighting unit as standard.

The VSX 2000 requires very little maintenance and is characterised by its great ease of use.

Sorting performance:

2,200 eggs / hour

Scales:

The scales – the centrepiece of every sorting machine – are also made of stainless steel. Through regulation of the weights system, every weight class can be set with the highest precision.

Hygiene:

To facilitate cleaning and to ensure a high standard of hygiene, the casing, scales, and egg inspection table in our machines are made from stainless steel as standard.

Options:

An egg counter and egg labelling are optionally available for the VSX 2000.